Drones are transforming the way farmers spray their crops, making the process more efficient and precise. With the ability to cover large areas quickly, drones can significantly reduce the time and labor required for agricultural spraying.

According to a study, drones can spray up to 40 acres of land in just one hour, which is a huge improvement over traditional methods. This increased efficiency allows farmers to spray their crops more frequently, which can lead to healthier and more productive crops.

Drones equipped with precision spraying systems can apply the exact amount of fertilizer or pesticide needed, reducing waste and minimizing the environmental impact of agricultural spraying.

Intriguing read: Dji Agricultural Drones

Components and Technology

Drone sprayers are equipped with all the essential components of large ground sprayers and conventional aerial sprayers. These include a tank, pump, pressure gauge, hoses, filters, nozzles, and a flow meter for real-time rate adjustments.

Each component plays a critical role in achieving maximum sprayer performance. For instance, the tank holds the liquid to be sprayed, while the pump ensures it's delivered at the right pressure. The pressure gauge helps monitor this pressure, and the hoses connect the pump to the nozzles.

A drone sprayer's advanced technology also includes a GNSS receiver and multiple sensors for collision avoidance. This enables safe and precise spraying, even in tight spaces.

Components

Drone sprayers are equipped with all the necessary components to function effectively, much like their larger counterparts.

A tank is a crucial component, allowing the drone to store and carry the necessary liquid for spraying.

The pump is another essential part, responsible for pressurizing the liquid before it's released through the nozzles.

A pressure gauge helps monitor the pressure levels, ensuring the liquid is being released at the right force.

Hoses and filters are also vital components, helping to distribute the liquid evenly and prevent any clogs or blockages.

Nozzles are responsible for releasing the liquid in a controlled manner, allowing for precise spraying.

A flow meter allows for real-time rate adjustments, enabling the drone to adjust its spraying speed as needed.

Drone sprayers also come equipped with a GNSS receiver, which helps with navigation and collision avoidance.

Multiple sensors are used to detect and avoid obstacles, ensuring safe operation.

Each component plays a critical role in achieving maximum sprayer performance.

Here's a breakdown of the main components of a drone sprayer:

- Tank

- Pump

- Pressure gauge

- Hoses

- Filters

- Nozzles

- Flow meter

Components and Technology

Before you start using a drone for agricultural spraying, it's essential to inspect its components and follow the manufacturer's maintenance schedule. This ensures your drone is in good working condition and reduces the risk of mechanical failures during flight.

To minimize drift, it's crucial to be aware of the potential for drift and develop a plan to minimize it. This involves considering the wind direction, speed, and other environmental factors that could impact the spray pattern.

If you're mixing tank loads near the drone take-off and landing area, be prepared for a large amount of debris to be kicked up during take-off and landing, contaminating the tank loads. To prevent this, consider using lids on the tank loads.

AcuSpray's agricultural drone spray services utilize cutting-edge drone technology that ensures precise spraying, targeting specific areas with accuracy. This precision is achieved through the use of advanced drone technology.

Here are some key components and technologies used in drone spraying:

- Drone components: inspected and maintained according to the manufacturer's schedule.

- Drone technology: cutting-edge, ensuring precise spraying and targeting specific areas.

- Tank loads: lids used to prevent debris from contaminating the loads during take-off and landing.

Best Practices and Efficiency

Before starting an agricultural spraying application with a drone, it's essential to check the FAA's website for Temporary Flight Restrictions (TFRs) and Notice to Airmen (NOTAMS). This will help you avoid any potential issues or hazards.

To ensure a smooth operation, inspect your drone's components and follow the manufacturer's maintenance schedule. This will help prevent any technical issues during the spraying process.

Be aware of the potential for drift and develop a plan to minimize it. This is crucial for efficient and effective spraying.

Here are some key factors to consider for efficient drone spraying:

By following these best practices and considering the efficiency gains of drone spraying, you can optimize your agricultural operations and achieve better results.

Best Practices

Before you start any application, it's essential to check the FAA's website for Temporary Flight Restrictions (TFRs) and Notice to Airmen (NOTAMS). This will help you avoid any potential hazards and ensure a smooth operation.

To ensure the longevity of your equipment, inspect your drone's components and follow the manufacturer's maintenance schedule. Regular maintenance is crucial for optimal performance.

Reading and following the pesticide label is a must, as it provides critical information on safe usage and handling. Don't skip this step, as it can save you from potential accidents and damage.

To minimize drift, be aware of the potential for it and develop a plan to mitigate its effects. This will help you maintain control and precision in your application.

When mixing tank loads near the drone take-off and landing area, be prepared for debris to be kicked up during take-off and landing procedures. To prevent contamination, consider using lids on your tank loads.

Efficiency Gains & Savings

By streamlining operations and minimizing waste, drone spraying solutions deliver significant cost savings and efficiency gains.

Drone spraying can cover large areas quickly, allowing farmers to complete tasks in a fraction of the time compared to traditional methods. This can lead to significant savings over time, especially for farmers with large fields.

The DJI Agras T25, for example, can cover up to 12 hectares per hour with a 20 kg spraying payload and up to 25 kg of spreading payload capacity.

Here are some key statistics on the efficiency of drone spraying:

By automating the spraying process, farmers can save on labor costs and reduce the amount of product used, leading to significant savings over time.

Frequently Asked Questions

How much does drone spraying cost per acre?

Commercial drone applicators typically charge $11-14 per acre for their services, which is comparable to traditional aerial applications.

Can I spray pesticides with a drone?

Yes, drones can be used to spray pesticides, offering a more efficient and safer alternative to traditional methods. They reduce the risk of applicator contamination and can handle small, irregular-shaped fields.

What are the disadvantages of drone spraying?

Drones used for crop spraying can pose a risk to people and animals if they malfunction or are not operated correctly, potentially causing harm or injury

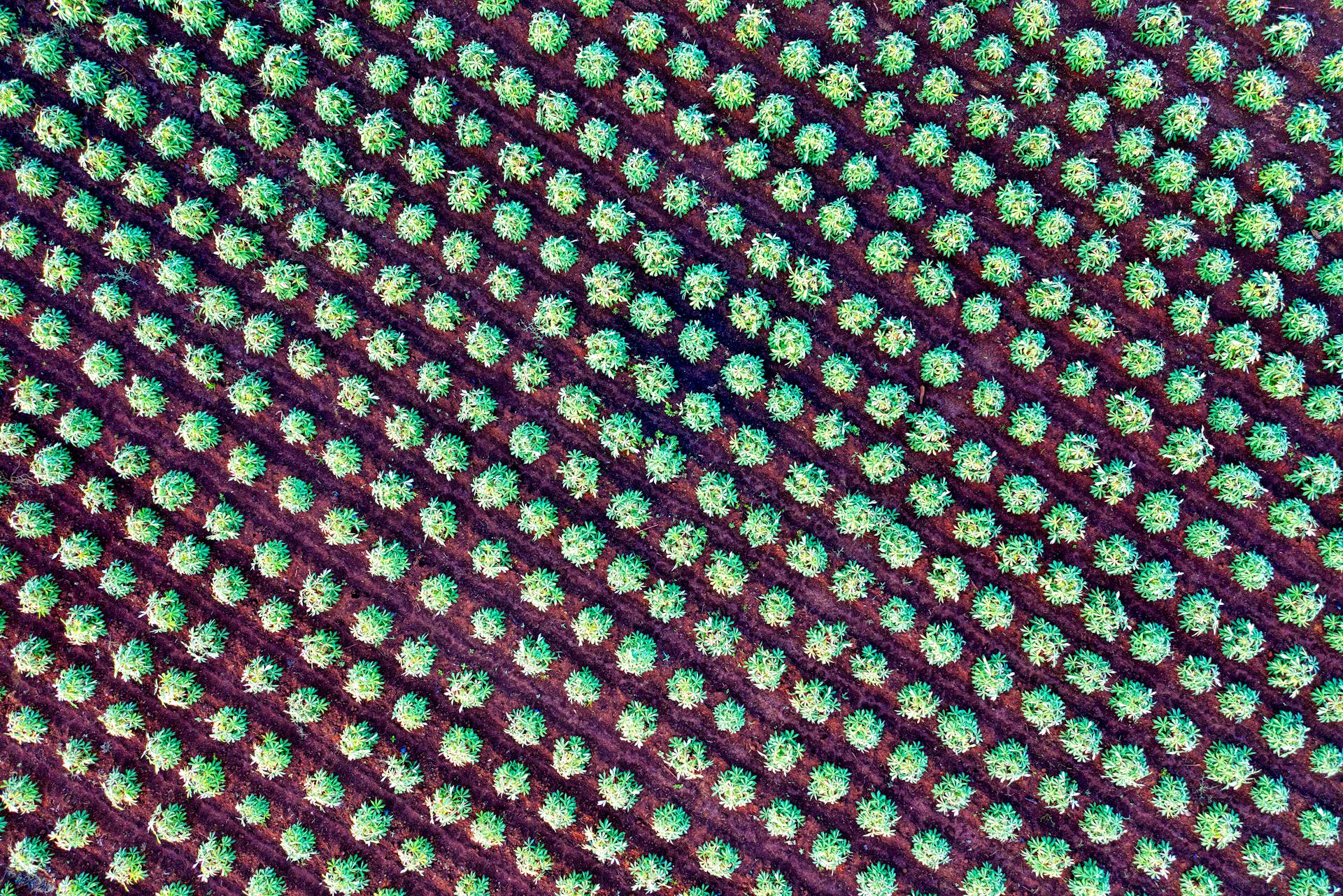

Featured Images: pexels.com